Electrifying snack production with heat batteries and green electricity

Partnership of PepsiCo, Eneco, TransitionHERO, Kraftblock and Liander

At PepsiCo’s snack factory in Broek op Langedijk, the Netherlands, electricity is replacing natural gas as the main source of heat. Soon, a new high-temperature heat battery system will power the frying process entirely with renewable electricity, replacing the use of fossil fuels. This marks the first project of its kind in the Dutch food industry.

The Volt project Developed in partnership with PepsiCo, Eneco, TransitionHERO, Kraftblock and Liander, the project, called Volt, represents a breakthrough in industrial electrification. It demonstrates how surplus renewable electricity can be stored as heat and used continuously in production, cutting emissions and reducing dependence on fossil fuels.

Developed in partnership with PepsiCo, Eneco, TransitionHERO, Kraftblock and Liander, the project, called Volt, represents a breakthrough in industrial electrification. It demonstrates how surplus renewable electricity can be stored as heat and used continuously in production, cutting emissions and reducing dependence on fossil fuels.

"This project shows that electrification of industrial heat isn’t just possible, it’s practical, efficient and scalable", says Greg Wessels, Project Manager at TransitionHERO, the engineering firm supporting the initiative. "By using stored green electricity for high-temperature heat, we are tackling one of the toughest challenges in industrial decarbonization."

Decarbonizing snack production

PepsiCo’s snack production lines in Broek op Langedijk currently rely on large gas-fired boilers to provide hot oil at 260 °C required for frying. To drastically cut emissions PepsiCo is now preparing to electrify its heat supply by introducing renewable electricity from wind and solar power.

Electrifying the frying process is a key step in PepsiCo’s ambition to reach net-zero emissions by 2040. The new installation, which is currently being built, will allow renewable electricity to replace natural gas for process heat, significantly reducing the site’s carbon footprint while stabilising longterm energy costs.

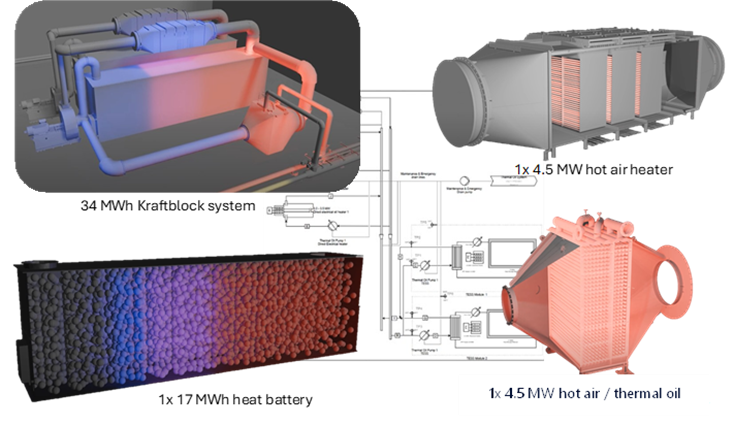

Eneco developed the asset and will operate the installation under a heat-as-a-service model. The system consists of electric heat generators, a high-temperature thermal storage unit, and discharge equipment that transfers the stored heat to the frying process. Once commissioned, it will charge whenever renewable electricity is available on the grid and discharge stored heat when demand peaks. This setup will enable flexible use of green power while maintaining continuous production.

At the Broek op Langedijk site, where approximately 1,6 million bags of Lay’s and Cheetos are produced each year, the new system will eventually replace 21 MW gasfired boiler capacity with a thermal storage installation, with useful capacity of 34 MWh in its first phase. When fully operational, it is expected to reduce annual CO2 emissions by about 8,500 tonnes, or roughly 50%.

It is expected to reduce annual CO2 emissions by 50%

The planned scale-up to extra useful capacity of 70 MWh could increase this to as much as 98%, avoiding the use of 9 million cubic metres of natural gas per year. This transition will also prevent an estimated 7 tonnes of NOₓ emissions annually, contributing to improved local air quality alongside the reduction in CO2.

Why thermal storage?

In the early concept phase, several alternatives were evaluated by TransitionHERO, including chemical batteries, hot liquid storage, electrical battery and lower-temperature storage systems. High temperature heat storage was ultimately selected as it offers the highest overall efficiency, safe operation, relatively compact footprint and cost competitiveness.

Choosing the right technology

To identify the most suitable solution for electrifying PepsiCo’s heat supply, TransitionHERO executed a comprehensive technology scouting study and multi-criteria analysis. A total of 15 technologies were scouted and evaluated on technical performance, temperature range, efficiency, scalability, technical readiness level (TRL) and economic feasibility.

In parallel, TransitionHERO developed a model, known as the optioneering tool to run more than 1.000 scenarios, enabling the team to determine the most suitable system configuration and design capacity. The model incorporated PepsiCo’s hourly production data, energy consumption profiles, grant thresholds, and both CAPEX and OPEX estimates. This approach helped to identify the optimal balance between technical performance and financial viability under real operating conditions.

"We wanted to make sure the technology choice wasn’t just the most innovative, but also the most practical", explains Stef Clevers, Energy expert and Co-founder at TransitionHERO. "By combining technology scouting with our optioneering tool, we could test over a thousand scenarios and select the design that offered the best balance between technical performance and economic feasibility."

Key questions included:

- How much energy must be stored to maintain continuous production?

- What charging and discharging speeds are required?

- Which technology offers the highest efficiency at the target temperature?

Based on this detailed evaluation, Kraftblock’s high-temperature thermal storage was selected as the most promising technology. The Kraftblock system can store heat between 800 and 1.300 °C with an efficiency of around 95% based on 24-hour charge discharge cycle, using proprietary storage materials that retain thermal energy over many cycles.

In Kraftblock’s operation, heat is discharged by blowing ambient air through the storage medium, creating a sharp temperature front that gradually moves from the hottest material toward cooler zones. This design enables the system to operate for long periods at high thermal output, maintaining maximum charging and discharging duty (in MW) over many operating hours. These high operating temperatures were essential for integration with PepsiCo’s frying process; lower-temperature systems would have required significantly larger storage volumes and higher costs.

TransitionHERO now acts as owner’s engineer, overseeing detailed design, validating technical documentation, and coordinating between project partners to ensure the technology performs as intended and meets PepsiCo’s operational, safety, and quality standards.

Ensuring reliability and continuity

Because PepsiCo’s production runs 24/7, any interruption in heat supply would have major consequences. To ensure continuous operation and increase overall system efficiency when power is available, the system design includes a redundant backup system with two 3 MW direct electric oil heaters that can supply process heat directly from electricity, bypassing the heat battery system.

Furthermore, a hot oil buffer, configured as a stratification tank, is also integrated into the circuit to stabilise flow and smooth short-term fluctuations in production demand.

This configuration guarantees operational reliability during maintenance, grid constraints or unexpected downtime. When powered by renewable electricity, the backup system remains fully aligned with PepsiCo’s sustainability objectives, providing resilience without increasing emissions.

Electrical infrastructure and smart grid integration

Switching from gas to electricity required major upgrades to the plant’s power infrastructure. Liander, the regional grid operator, played an important role in this aspect of the project. A new six-kilometre high-capacity cable connection was installed to increase electrical capacity and enable rapid charging of the storage system during periods of high renewable generation.

The true innovation, however, lies in the contracting structure between PepsiCo, Eneco, and the grid operator. Traditionally, industrial users can only draw electricity up to their contracted capacity. In this project, a flexible connection agreement was introduced, allowing PepsiCo to use the system when sufficient power and transmission capacity are available on the grid.

"Integrating Information and Operational Technology (IT/OT) across different organisations and multiple assets onsite has been a key challenge", explains Youri Nattekaas, Electrical and Instrumentation lead engineer at TransitionHERO. "The project requires a secure, real-time data connection between the production site and Eneco’s trading room to allow the system to respond dynamically to market and grid conditions."

"Integrating IT and OT across different organisations and multiple assets onsite has been a key challenge"

This arrangement not only contributes to more sustainability but also helps balance the power grid by absorbing excess renewable energy, particularly during periods of strong wind or solar production. While the pilot required regulatory approval, it opens the door to new contractual models for industrial electrification.

To make this dynamic operation possible, Eneco can operate the system based on realtime wind and solar forecasts and grid imbalance signals. An advanced IT/OT architecture was developed to ensure secure data exchange between the PepsiCo production site and Eneco’s trading and control systems. This digital link allows Eneco to optimise the system’s operation, aligning charging and discharging with grid conditions and the availability of renewable energy while maintaining data security and operational integrity.

Financial framework, subsidies and project timelines

One of the biggest challenges in electrifying industrial heat is the cost difference between gas and electricity. Depending on market conditions, electricity can be significantly more expensive per unit of energy, making operational costs a key consideration.

To make the project financially viable, Eneco secured support through the SDE++ subsidy scheme. This Dutch government programme compensates for the cost gap between renewable and fossil-based energy for a specified number of operational hours each year. The subsidy ensures that renewable electricity remains competitive with natural gas, particularly during periods of high electricity prices. Futhermore also CAPEX subsidy DEI+ scheme was be secured to support this project.

Project impact and broader significance

The Volt project showcases how large industrial players can adopt flexible high temperature heat storage technologies to achieve deep decarbonization. By combining high-temperature thermal storage, smart system integration, and innovative business models, PepsiCo and Eneco have created a replicable blueprint for other energy-intensive sectors.

For Eneco, the project demonstrates the potential of offering heat as a service, providing customers with carbon-neutral process heat without requiring them to invest in new infrastructure. For TransitionHERO, it highlights the value of independent engineering support in scaling emerging technologies safely and efficiently. For Kraftblock, the installation represents a key milestone in validating its technology under real industrial conditions. And for PepsiCo, it is a major step forward in its global ambition to achieve net-zero emissions by 2040.

Looking ahead

As the system moves from design to operation, continuous monitoring will ensure optimal performance and provide insights for future replication. The lessons learned, from grid contracting and subsidy structures to system integration and risk management, will be valuable for the broader manufacturing sector.

Thermal energy storage is poised to play an increasingly important role in industrial decarbonization. Projects like Volt show that with the right combination of technology, collaboration, and regulatory flexibility, even complex heat-driven processes can be powered sustainably.

By transforming renewable electricity into reliable, high-temperature heat, PepsiCo’s Dutch snack plant demonstrates that the energy transition is not a theoretical exercise, it’s being implemented, right now, on the factory floor.